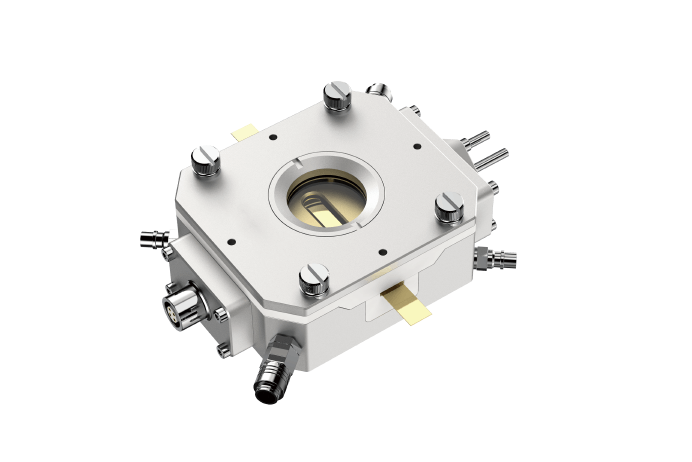

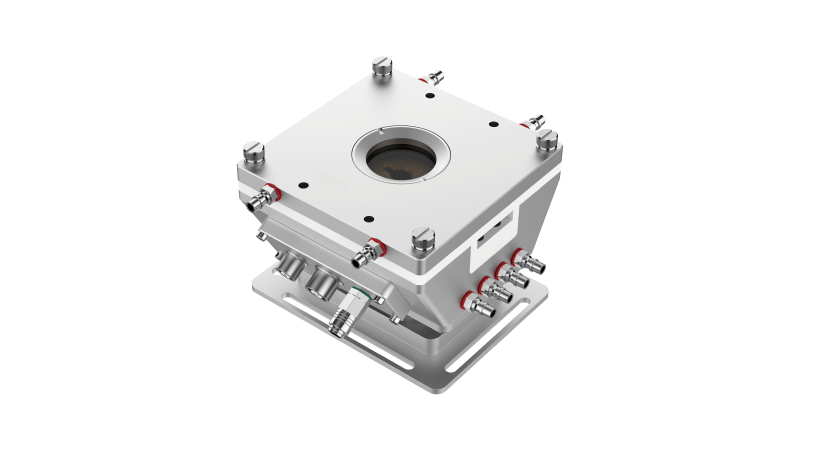

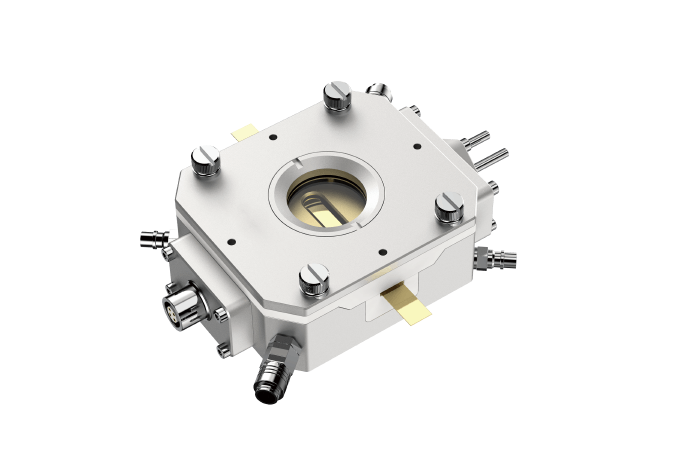

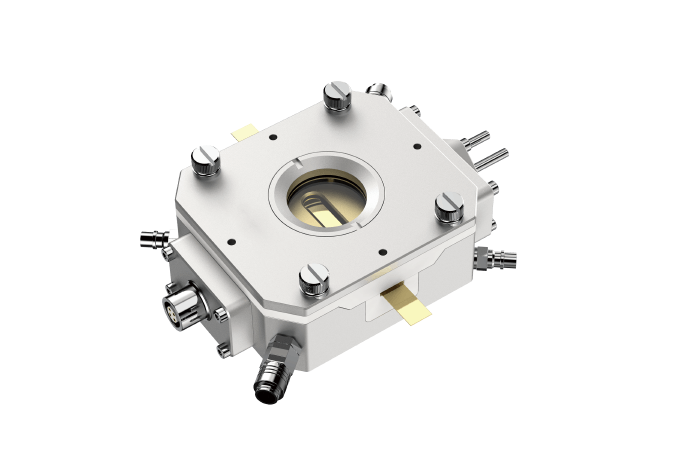

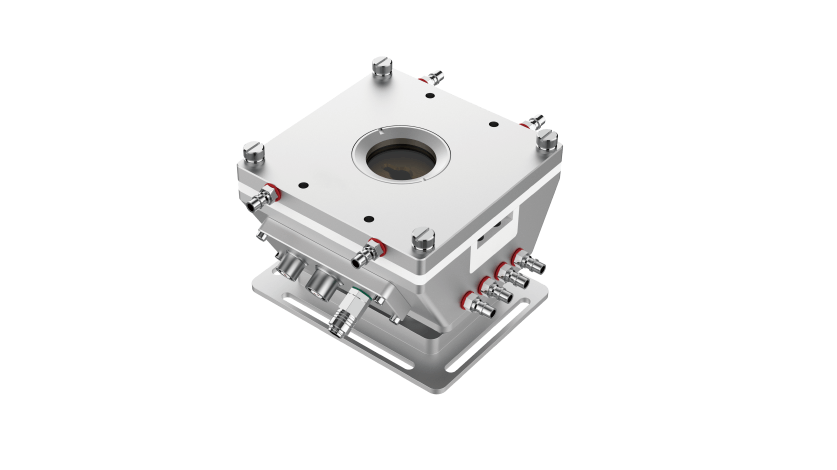

VL Heating and Cooling Tensile Stage

An important equipment for the study of the micromechanical properties of materials

- Precise temperature control

- Diverse mechanical tests

- Convenient in-situ observation

- Strong compatibility

Introduction to VL Heating and Cooling Tensile Stage:

By comprehensively applying advanced refrigeration and heating technologies, precise control of the temperature in the test environment is achieved. In terms of refrigeration, some models adopt liquid nitrogen refrigeration, which can quickly lower the temperature to an extremely low level, reaching -190°C, making it possible to study the brittle transition and cold brittleness of materials at low temperatures. For the heating function, high-efficiency resistance heating elements are mostly used, which can raise the temperature to 1000°C or even higher (depending on the specific model). Real-time monitoring is conducted through precision temperature sensors (such as thermocouples, PT100, etc.), combined with PID temperature control algorithms, to ensure that the temperature stability is maintained at an extremely high level. For example, it can reach ±0.1°C when the temperature is <600°C, and ±1°C when the temperature is >600°C.