光学型

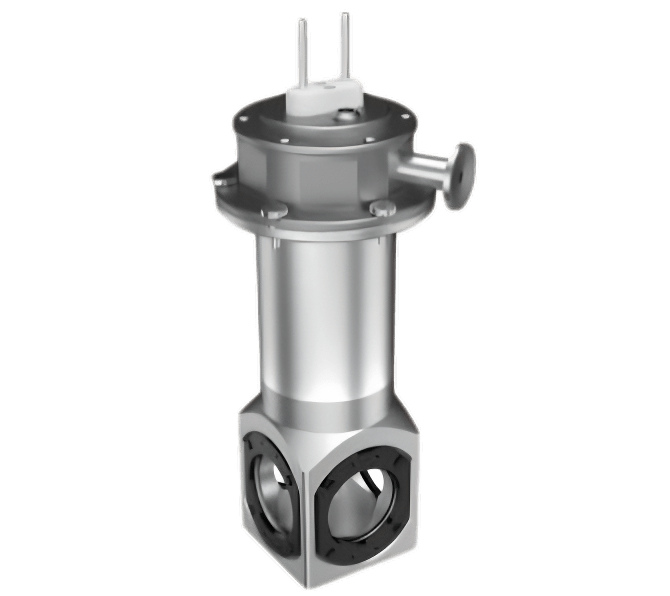

Multi-window heating and cooling stage for Spectrometer

Multi-window optical design and wide-temperature-range precision temperature control

- Multi-window Optical Adaptation System

- Wide Temperature Range Precision Temperature Control Technology

- High-efficiency Experimental Process Design

- Harsh Environment Adaptability

OptiThermo Stage

Universal temperature control technology + unified optical adaptability + consistent sample positioning system

- Compatibility with multi-scenario environments

- Intelligent temperature control integration

- Modular interface design

- Lightweight and compact design

VL Optical Heating and Cooling Stage

The silver sample stage has uniform thermal conductivity, ensuring temperature consistency. The window material is JGS2 quartz glass, which has excellent light transmission performance.

It covers a wide temperature range from ultra-low to medium-high temperatures, meeting the needs of multi-scenario testing.

VL Optical Heating and Cooling Stage

It has low-temperature performance, with a lightweight and small-sized body, making it more suitable for scenarios with limited installation space.

The temperature control rate meets the requirement of rapid temperature change, and it can be used for biophotonics testing in the biomedical field.

VL Optical Heating and Cooling Stage

The ultra-thin structure breaks through the limitation of installation space and is compatible with compact optical devices.

The size of the lower window is φ10mm×0.5mm (transmission optional), which is suitable for high-resolution optical testing.

VL Optical Heating and Cooling Stage

It features both an ultra-thin structure and low-temperature performance. The vacuum chamber reduces external interference, making it suitable for scenarios with strict requirements on installation space and testing environment.

The window defrosting design ensures observation clarity at low temperatures, and it is applicable to small optical experiments in the field of space science.

VL Optical Heating and Cooling Stage

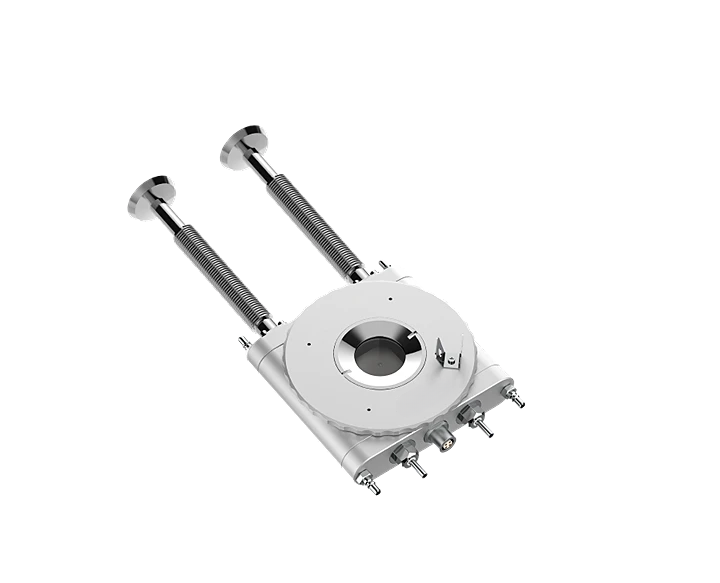

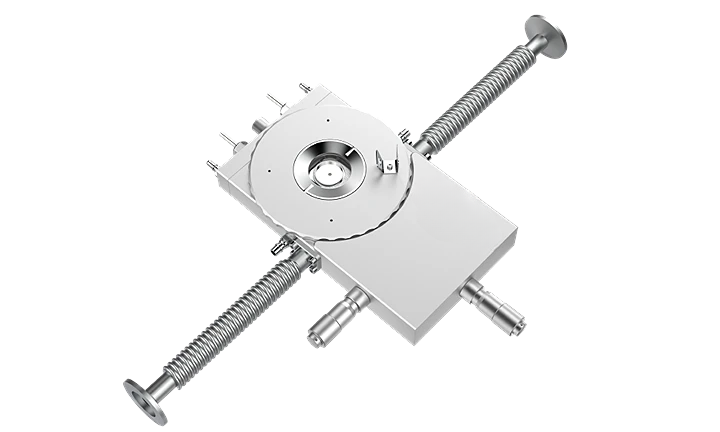

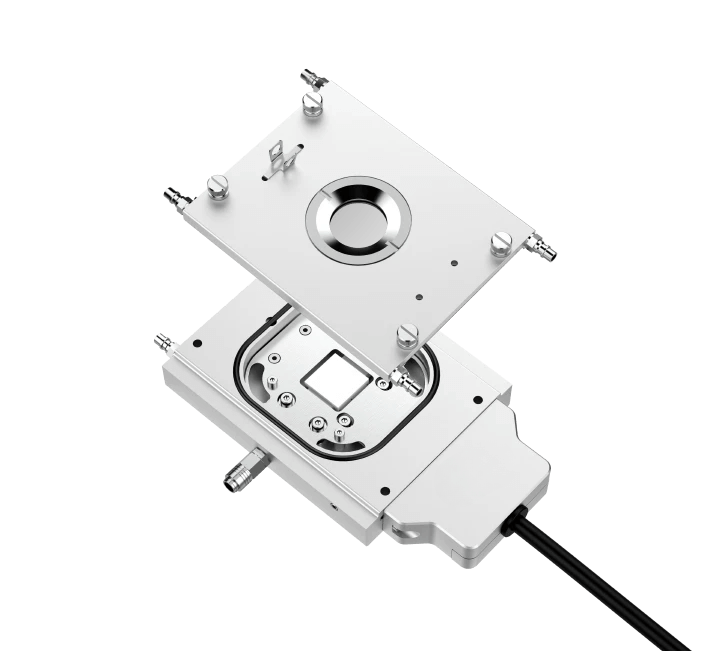

The XY axis displacement enables precise positioning of the sample without the need for manual adjustment of the sample position, improving testing efficiency.

The wide temperature range combined with displacement function is suitable for scenarios requiring multi-point testing and compatible with various optical instruments.

VL Optical Heating and Cooling Stage

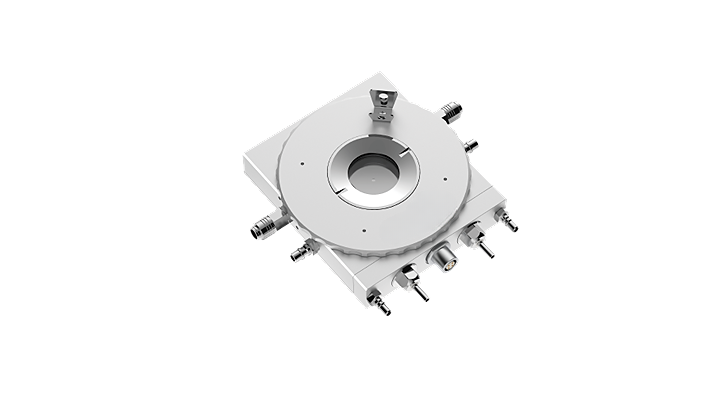

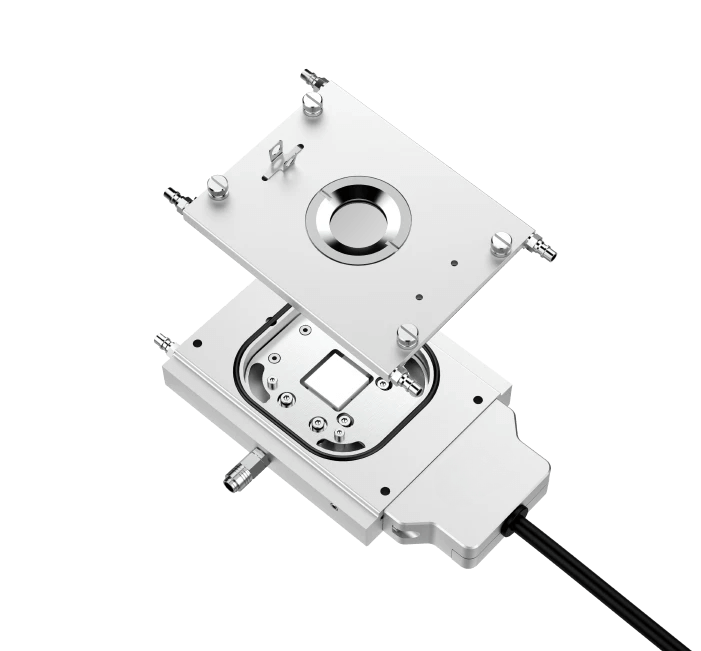

XY axis displacement ensures precise positioning of samples, with stable low-temperature performance.

The vacuum chamber is suitable for testing sensitive samples, and compared to models without displacement, it is more suitable for low-temperature experiments that require multi-point observation.

PeltierThermo Stage

The core temperature control methods are unified, the basic optical adaptations are consistent, and the temperature control accuracy is stable.

- Lightweight structural design

- Convenient sample operation

- Flexible adaptation to multiple scenarios

- Strong adaptability of temperature control rate

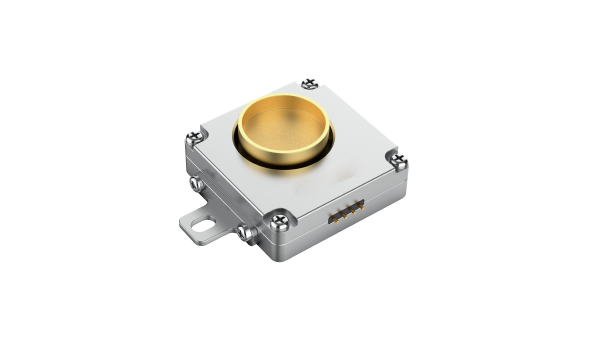

VL Peltier Heating and Cooling Stage

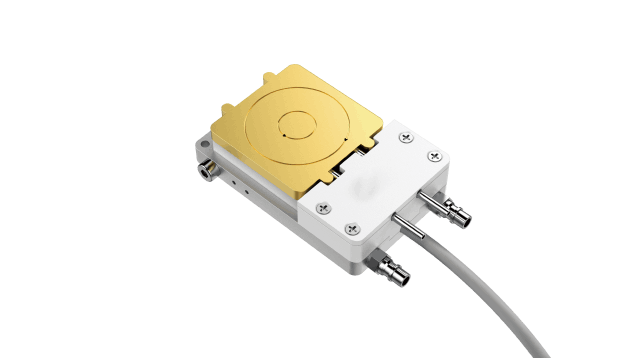

The lightweight and thin design allows for easy integration, making it suitable for scenarios with strict requirements on device volume.

The Peltier cooling has a rapid response, with a temperature rise and fall rate of 30℃/min, which can quickly reach the target temperature and save testing time.

VL Peltier Heating and Cooling Stage

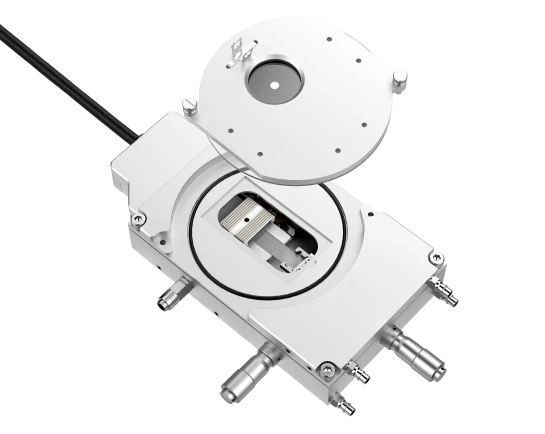

The atmosphere chamber can reduce the impact of sample oxidation, moisture absorption, etc., and is suitable for testing samples sensitive to the environmental atmosphere.

The larger body size makes the internal structure layout more reasonable and the heat dissipation effect better, ensuring stable operation for a long time.

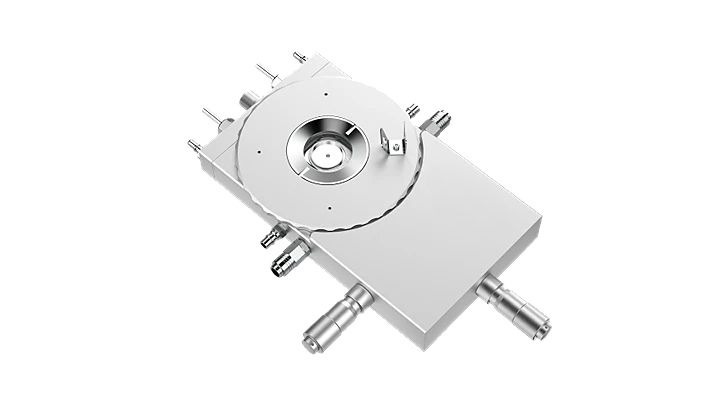

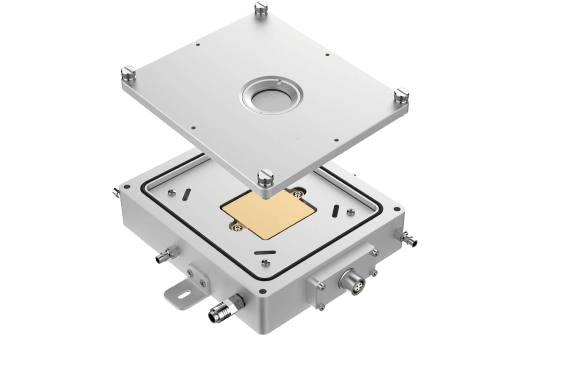

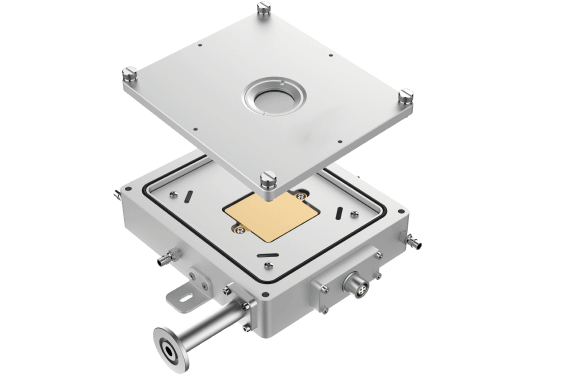

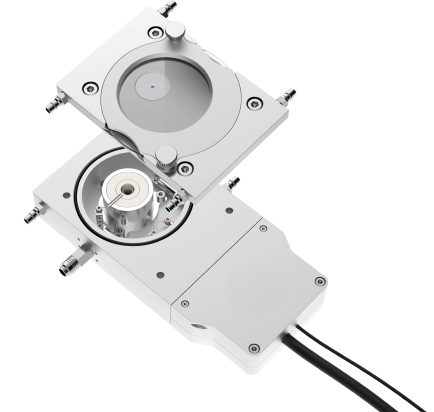

VL Peltier Heating and Cooling Stage

A vacuum environment greatly reduces interferences such as air convection and impurity adsorption, making it suitable for scenarios with extremely high requirements for testing environments.

For example, high-precision optical inspection of semiconductor chips can obtain purer optical signals and improve testing accuracy.

OptiHeat Stage

Good optical adaptability + flexible chamber design + diverse temperature control methods

- Wide temperature range coverage

- Compact structure

- High degree of customization

- Convenient software control

VL Optical Heating Stage

It is small in size, light in weight, and takes up little space, making it easy to use in scenarios with limited installation space.

It is easy to operate and can be quickly put into experiments without complex debugging.

VL Optical Heating Stage

The temperature range covers the medium temperature interval, supports dual optical path mode, and is compatible with more optical testing requirements.

The atmosphere chamber can reduce interference from the external environment, ensure experimental accuracy, has a compact structure and moderate weight, and balances performance and portability.

VL Optical Heating Stage

The maximum temperature reaches 800℃, which can meet the testing requirements of high-temperature materials. The stainless steel sample stage is resistant to high temperatures and corrosion, with a long service life.

The dual optical path mode is compatible with various devices such as Raman spectrometers, making it applicable to a wider range of scenarios.

UltraHot Stage

Precise temperature control technology + wide temperature range coverage + optical path and window design

- Excellent high-temperature performance

- Comprehensive customized services

- Compact structure and easy operation

VL Ultra-High-T Heating Stage

Temperature control is precise and stable, the ceramic sample stage is resistant to high temperatures, and the structure is compact.

It is suitable for conventional high-temperature material testing scenarios, with convenient installation and operation.

VL Ultra-High-T Heating Stage

The top cover circulating water protection function enhances the safety of equipment during high-temperature operation and meets the testing requirements for materials in medium to high temperature ranges.

It is suitable for high-temperature material testing where safe operation of equipment needs to be ensured below 1200℃, such as observing the high-temperature structural stability of ceramic materials.

VL Ultra-High-T Heating Stage

It has a high upper temperature limit (1500℃), and the furnace chamber-type sample stage is suitable for precise placement of small samples.

The transmission optical path meets specific observation needs, and the eccentric rotating window ensures the clarity of the field of view.

VL Ultra-High-T Heating Stage

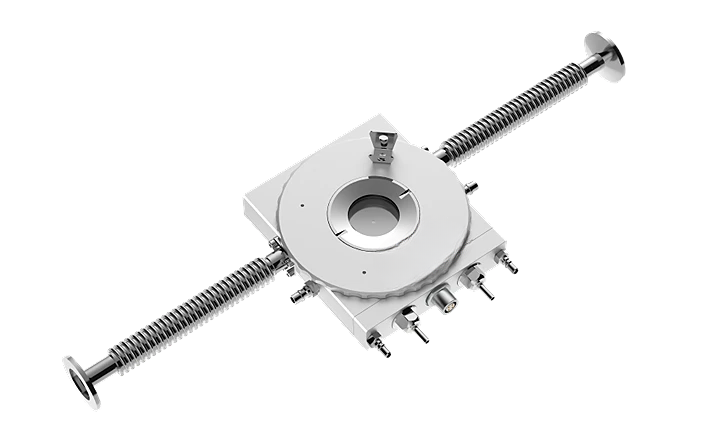

It has the function of sample XY axis displacement, which can accurately adjust the sample observation position.

The tunnel-type sample stage is suitable for long strip samples or samples that need to be observed at multiple positions, and its upper temperature limit meets the needs of medium and high temperatures.

Infrared Heating Furnace

Equipment that uses infrared radiation for heating

- Fast heating speed

- Precise temperature control

- Energy-saving and environmentally friendly

- Flexible heating methods