力学型

Temperature Controlled Stages for mechanical testing

Study on Material Properties under Temperature-Mechanical Coupling Environment

- Wide temperature range + high-precision temperature control

- Strong adaptability

- Extensibility of multi-field coupling

- Accurate data synchronization

Temperature Controlled Stages for mechanical testing

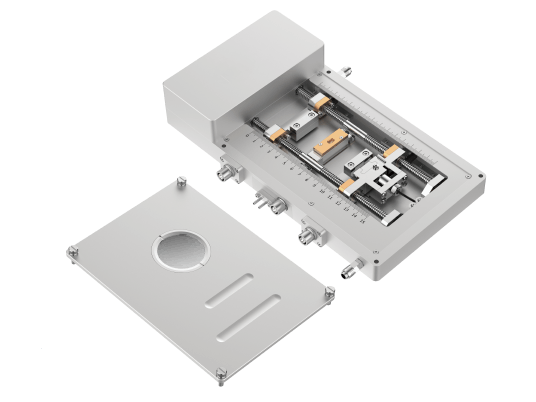

LN600S-T is a liquid nitrogen temperature control stage specially designed for material tensile mechanical testing. Its core function is to provide a stable temperature environment for tensile experiments within a wide temperature range of -170℃ to 500℃. Its dog-bone shaped sample slot is suitable for standard tensile samples (such as metals and polymer materials).

It isolates external interference through a vacuum chamber, avoids high-temperature oxidation or low-temperature frosting, and ensures accurate measurement of parameters such as tensile strength and elongation at break.

Temperature Controlled Stages for mechanical testing

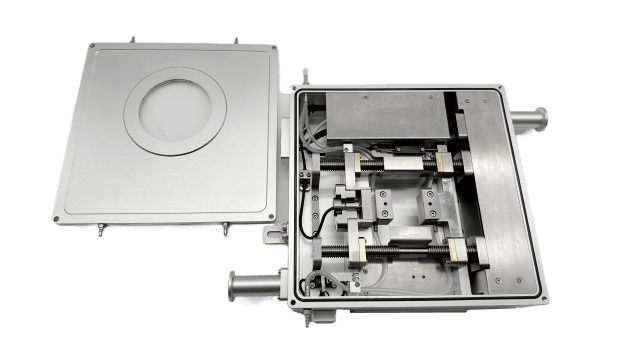

LN600S-C is a liquid nitrogen temperature control stage specifically for compressive mechanical testing. It is designed for block and columnar samples (such as ceramics, rocks, and biological materials) and can simulate the compressive strength, elastic modulus, and buckling behavior of materials over a wide temperature range.

Its small-sized sample slot is suitable for micro samples, and when combined with a vacuum environment, it prevents samples from absorbing moisture at low temperatures or structural collapse at high temperatures.

Tensile Stage

Precision testing equipment dedicated to research on the synergistic evolution of material mechanics - microstructure

- Multimodal mechanical testing

- Wide temperature range

- High-precision control

- In-situ observation capability

- Modular design

VL In-situ Stretching Stage

Advantages:

High precision in temperature control within the medium and low temperature range, suitable for studying the mechanical properties of temperature-sensitive materials within this temperature range. Additionally, the liquid nitrogen refrigeration method has relatively low costs and fast cooling speed. Meanwhile, the multi-mode temperature control can flexibly adapt to different experimental requirements.

Applications:

Suitable for testing the mechanical properties of polymer materials such as rubber and plastic in medium and low temperature environments, such as studying the influence of temperature on the elastic modulus of rubber; it can also be used for researching the toughness changes of some metal materials at low temperatures.

VL In-situ Stretching Stage

Advantages:

It has outstanding capabilities in mechanical testing under high-temperature environments. The high-precision measurement system can provide accurate data for the analysis of the mechanical properties of materials at high temperatures, which is conducive to in-depth research on the relationship between the microstructure and mechanical properties of materials at high temperatures.

Applications:

It is often used for testing the mechanical properties such as tensile strength and creep of metal alloy materials at high temperatures, for example, in the research on the material properties of high-temperature alloy components in aero-engines; it can also be used for testing the strength of ceramic materials at high temperatures, etc.

TensileThermo Stage

An important equipment for the study of the micromechanical properties of materials

- Precise temperature control

- Diverse mechanical tests

- Convenient in-situ observation

- Strong compatibility

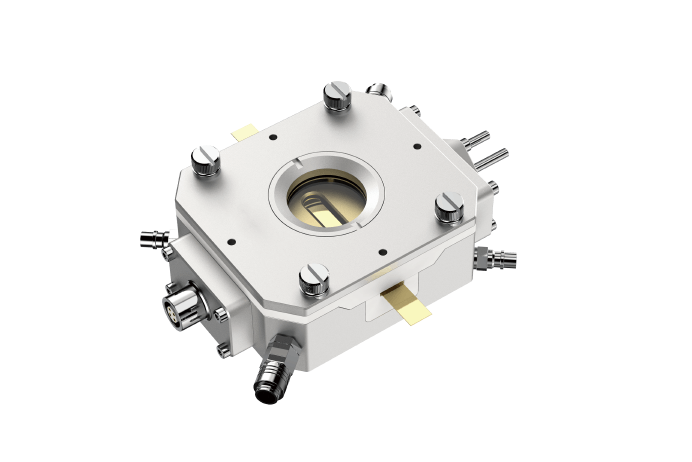

VL Heating and Cooling Tensile Stage

Advantages:

It can meet the needs of mechanical property testing for various materials in environments ranging from extremely low temperatures to medium-high temperatures, with a wide range of applicable materials. Stable temperature control can effectively reduce the interference of temperature factors on experimental results, improving the reliability and accuracy of experimental data. The compact and lightweight design allows for convenient placement even in laboratories with limited space, and it is relatively easy to move and operate.

Applications:

It is suitable for mechanical property testing of most conventional materials over a wide temperature range, such as toughness testing of metal materials at low temperatures, tensile property testing of polymer materials at different temperatures, etc.; it is also suitable for laboratories with restrictions on the installation space of experimental equipment.

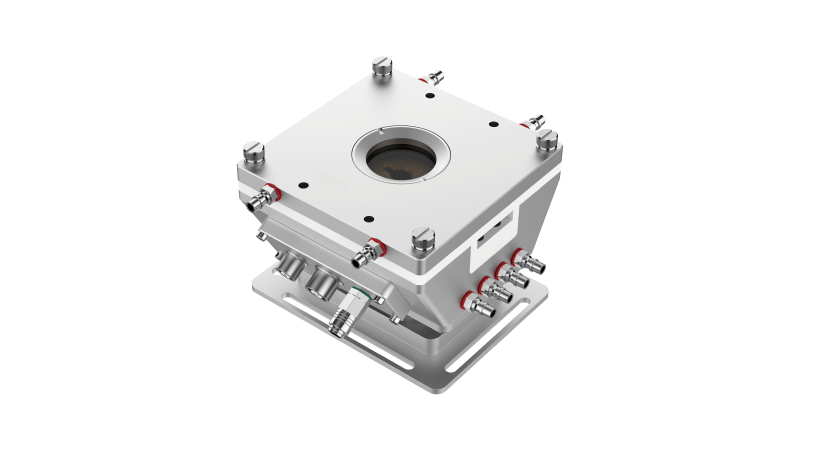

VL Heating and Cooling Tensile Stage

Advantages:

The larger sample stage can hold larger-sized samples, making it suitable for testing some special or large-sized material samples. Although it is larger and heavier in appearance, it is relatively more stable in some experiments with high requirements for equipment stability, which can reduce the impact of equipment shaking on experimental results.

Applications:

It is suitable for scenarios that require testing the mechanical properties of large-sized material samples at different temperatures, such as tensile, compression and other mechanical experiments on large metal components, special-sized composite materials, etc. in extreme temperature environments; it is also applicable to research environments with high requirements for equipment stability and sufficient laboratory space.