Venuslab-ISP CMOS Camera

Achieved a balance between "professional performance and high cost-effectiveness"

- Hardware-level image processing engine

- High-sensitivity and low-noise imaging

- Full-scenario compatibility design

- Balance between high resolution and transmission efficiency

Introduction:

1. Professional Performance: Focusing on the core needs of microscopic imaging, with technical parameters benchmarking against scientific research-grade standards

Equipped with Sony Exmor, Exmor R/RS back-illuminated CMOS sensors , it adopts dual-layer noise reduction technology, with a minimum dark current of only 0.03mV (such as Venuslab-ISP45KP-B,) and a maximum G-light sensitivity of 5970mV/lux・s (Venuslab-ISP08KP-D). It can capture clear details in low-light and fluorescence imaging scenarios (such as live cell observation and GFP analysis), meeting the strict noise control requirements of scientific research-grade imaging.

The resolution ranges from 1.5 million to 45 million pixels . The top model, Venuslab-ISP45KP-A, can output ultra-high-definition images with a resolution of 8176×5616, which is suitable for observing precise structures under high-power microscopes (such as 100× objective lenses), such as semiconductor defect detection.

It integrates a 12-bit Ultra-fine™ hardware image signal processor (HISP VP), which can hardware-accelerate tasks such as Demosaic conversion, automatic exposure, ROI white balance, and gamma correction. Traditional software processing requires more than 50% of the computer's CPU resources, while this series, through hardware acceleration, enables 21-megapixel models to reach a frame rate of 17fps (Section 9.2.2), and 45-megapixel models to still maintain 8.1fps. It balances high resolution and real-time preview, avoiding the industry pain point of "high pixels leading to low frame rates".

2.High cost performance: Uncompromised performance, more controllable costs, balancing professional needs and procurement budgets

It adopts a CNC zinc-aluminum alloy shell and a structure without moving parts (avoiding failure points such as lens displacement and fan jitter), which not only reduces manufacturing costs but also improves long-term usage stability (the mean time between failures is 30% higher than that of models with moving parts). The front end is standard-equipped with an IR-CUT filter or dual AR coating , eliminating the need for users to purchase additional optical accessories and reducing subsequent investments.

The series covers multiple resolution ranges from 1.5 million (Venuslab-ISP01KP-A) to 45 million (Venuslab-ISP45KP-A) . For teaching demonstrations and routine pathological testing, models with 1.5 to 5 million pixels can be selected; for precision scientific research, models with more than 20 million pixels are suitable. This avoids "paying a premium for unnecessary high pixels" and meets professional needs under different budgets.

Features:

- High-quality imaging hardware

- Hardware ISP efficient processing

- Strong compatibility design

- Durable and low-cost

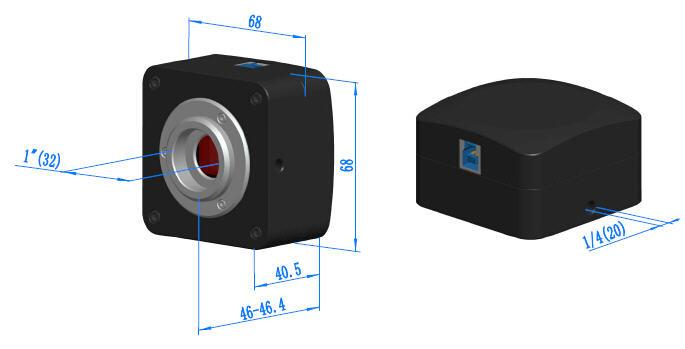

Dimension:

The Venuslab-ISP series body, made from tough, CNC aluminum alloy, ensures a heavy duty, workhorse solution. The camera is designed with a high quality IR-CUT to protect the camera sensor. No moving parts included. This design ensures a rugged, robust solution with an increased lifespan when compared to other industrial camera solutions.